Cart 0 Product Products (empty)

No products

To be determined Shipping

0,00 € Total

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart. There is 1 item in your cart.

Total products

Total shipping To be determined

Total

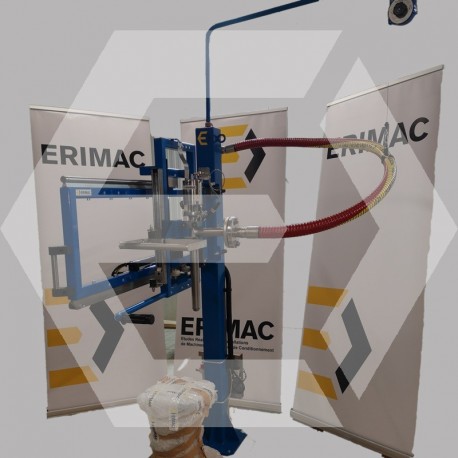

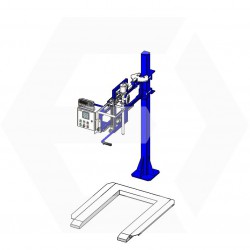

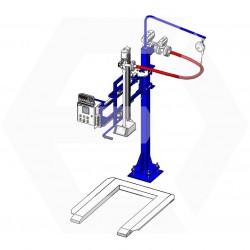

ERIFUT 3 XNP LT MANU

New product

The liquid filling machine ERIFUT 3 XP LT MANU allows the manual filling, of non-foaming product in IBCs, drums and containers.

Machine sold without dip tube.

Documentation 3XNP LT MANU

To order - deadline 5-6 weeks

Accessories

More info

DESCRIPTIONThe ERIFUT 3 XNP LT MANU allows packaging of non-foaming, pasty, liquid products in containers of different types.

| DOMAINS OF USEOur machines are designed for industrial exploitation.

| FEATURESMotion control

Filling Management

| ADVANTAGES

|

Data sheet

| Height | 1820 mm |

| Width | 600 mm |

| Depth | 1880 mm max |

| Weight | 80 kg |

| Use | Industrial use less than 1000 H / year |

| Rate | Up to 20 barrels / hour |

| Packaging | Drum and container |

| Product supply | Gravity, pump, pressure |

| Flow | Advocated 5 m³ / hour |

| Sound level | Less than 70 dB at 1m |

| General construction | Painted steel rust protection |

| Product circuit | Stainless steel 316L |

| Power supply | No need of electricity |

| Total power | 0 KW |

| Pneumatic supply | No need of air |

| Management height canes | Manual + spring support |

| Dive of cane | Partial diving (420 mm stroke) |

| Filling mode | On fixed level |

| Managing multi-level packaging | Yes with manual settings |

| Stroke adjuster of cane | Adjustable stroke in high and low position |

| Diameter of the cane | Diameter 40 mm default |

| Implantation on existing weighing | Yes, without slaving |

| Device filling | Without filling device |

| Management dosage packaging | Remplissage manuel |

| Rotation and translation braking | Optional |

| Documentation | Technical file including manual handling, mounting and connection, use, maintenance, spare parts list, EC certificate |

Ask a question

NO registration required!

If the question you have has not yet been answered here, use the form below to ask something about this addon.