No products

LT 3 AXIS SERIES

|  |  |

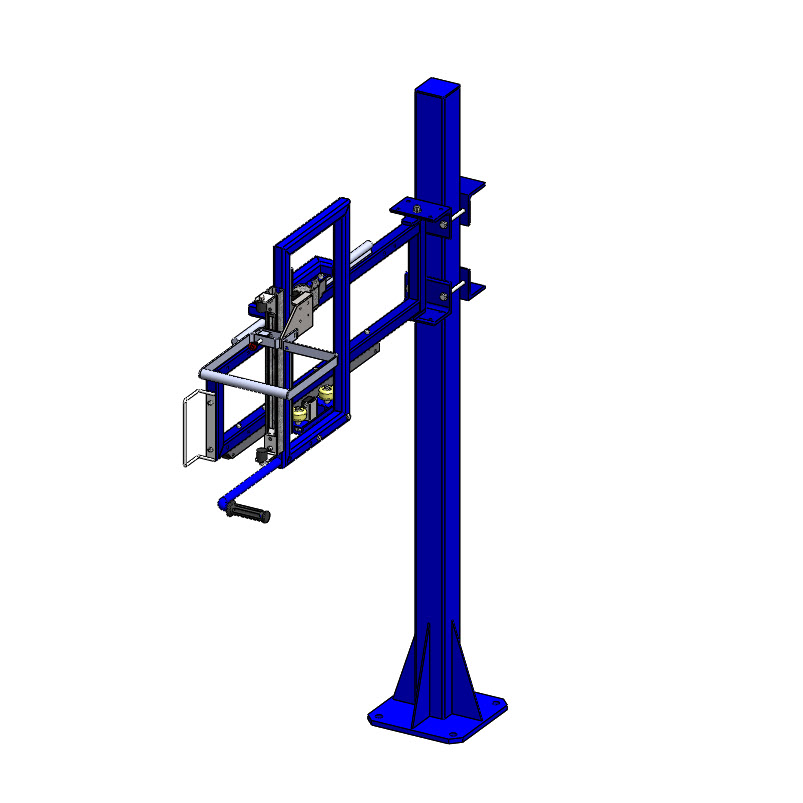

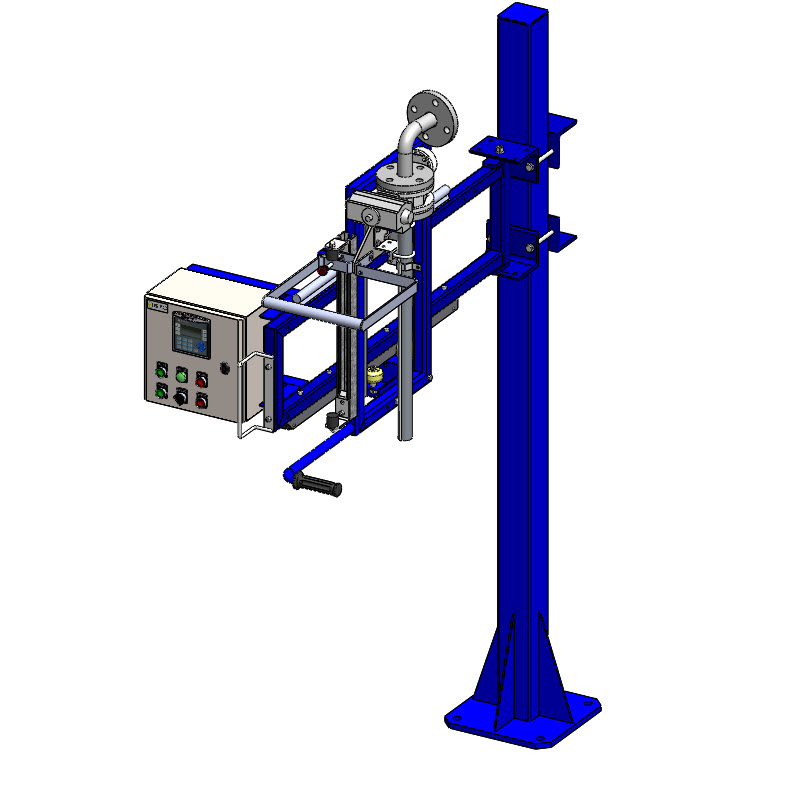

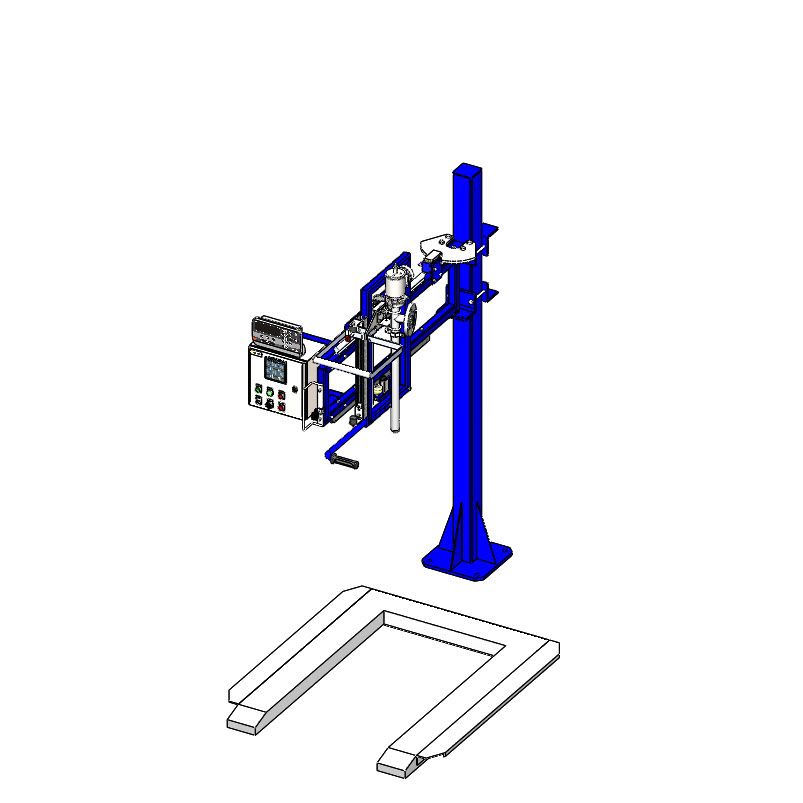

ERIFUT 3 XNP LT MANU | ERIFUT 3 XNP LT LEVEL | ERIFUT 3 XNP LT DOSING |

FUNCTION | ||

The ERIFUT 3 XNP LT MANU allows manual packaging container by a partial diving filling device. Conventional manual filling solutions with manual nozzel, dip tube or top loading arm exposes the operator to gaz eexaust and splashing, to a direct contact, during the handling and filling operations. The filling machine ERIFUT 3 XNP LT MANU replaces or combines advantageously existing conventional solutions.Improves conditions of handling and operator exposure in an improvement process complies with REACH requirements.

This configuration is ideal for the filling of 4 barrels on pallet or a container. The polar movement of filling device allows to cover partially the surface of a pallet. The diving system indexable (stroke 420 mm) to manually ensure diving the dip tube into the container with a blocking high and low position of the tube. The stops positioning units are adjustable in height to allow the modification of the race. An assist spring allows to help the rise of drumming device. Filling is performed by manually opening the valve of dip tube partiellement introduced in the container on level (filling fountain). Barreling adjustable arm height punctually with tools. | The liquid filling machine ERIFUT 3 XNP LT LEVEL allows the semi-automatic filling, of non-foaming product in of IBCs, drums and containers, by the partial introduction, in the packaging, of a dip tube with a detection of the level causing the stop of the filling. The ERIFUT 3 XNP LT LEVEL is ergonomically designed to optimize the conditions of handling and operator exposure in an improvement process complies with REACH requirements :

This configuration is an economical alternative for the semi-automatic filling of drums on a pallet or container The polar movement of filling device allows to cover partially the surface of a pallet. This configuration is ideal for the filling of 4 barrels on pallet or a container. The diving system indexable (stroke 420 mm) to manually ensure diving the dip tube into the container with a blocking high and low position of the tube. The stops positioning units are adjustable in height to allow the modification of the race. An assist spring allows to help the rise of drumming device. Filling is performed, based on a level, by an automatic filling cycle triggered by the operator. The level setting is manualy made according to a reference packaging or on a reference measure. Barreling adjustable arm height punctually with tools. | The ERIFUT 3 XNP LT DOSING allows the semi-automatic packaging in accordance with a target weight with a partial diving cane. The ERIFUT 3 XNP LT DOSING is ergonomically designed to optimize the conditions of handling and operator exposure in an improvement process complies with REACH requirements :

This configuration is ideal for the semi-automatic filling of 4 barrels on pallet or a container. The polar movement of filling device with locking in position allows to cover partially the surface of a pallet. The diving system indexable (stroke 420 mm) to manually ensure diving the dip tube into the container with a blocking high and low position of the tube. The stops positioning units are adjustable in height to allow the modification of the race. An assist spring allows to help the rise of drumming device. Filling is performed, based on a unit weight target, by an automatic filling cycle triggered by the operator Barreling adjustable arm height punctually with tools. |

INTEGRATION OF YOUR EXISTING | ||

|

|

|

MANAGEMENT DOSAGE PACKAGING | ||

|

|

Different weighing infrastructure are proposed according to your needs

|

BASE CONFIGURATION | ||

The base configuration includes:

Capacities: different format of barrel with bunghole or fully open and IBC containers Rates: following the flow of the pump, the viscosity of the product and local conditions, up to 30 barrels / h (40 barrels/h avec with conveyors) |

The base configuration includes:

Capacities: different format of barrel with bunghole or fully open and IBC containers Rates: following the flow of the pump, the viscosity of the product and local conditions, up to 30 barrels / h (40 barrels/h avec with conveyors) |

The base configuration includes:

Capacities: different format of barrel with bunghole or fully open and IBC containers Rates: following the flow of the pump, the viscosity of the product and local conditions, up to 30 barrels / h (40 barrels/h avec with conveyors) |

OPTIONAL EQUIPMENT | ||

|

|

|

ERIFUT 3 XP LT DOSING | EMPTYING DRUM ERIFUT 3 XP LT DF |

FUNCTION | |

The ERIFUT 3 XP LT DOSING allows the semi-automatic packaging in accordance with a target weight with a diving cane. The ERIFUT 3 XP LT DOSING is ergonomically designed to optimize the conditions of handling and operator exposure in an improvement process complies with REACH requirements :

This configuration is ideal for the semi-automatic filling of 4 barrels on pallet or a container. The polar movement (model L) with locking in position of the filling head is optimized for the filling 4 drums on pallets or IBC, it nevertheless allows the prompt filling of cans on pallets The motorized diving system (stroke 900) with pneumatic actuator allows the ascent and descent of the filling cane in the container with a blocking high and low position. Filling is performed, based on a unit weight target, by an automatic filling cycle triggered by the operator This configuration is ideal for the filling of foaming products in barrels or containers. | The emptying machne ERIFUT 3 XP LT DF allows the maual emptying of container with suction tube. Conventional manual emptying solutions with dip tube exposes the operator to gaz eexaust and splashing, to a direct contact, during the handling and filling operations. The ERIFUT 3XP LT DF replaces or combines advantageously existing conventional solutions. Improves conditions of handling and operator exposure in an improvement process complies with REACH requirements.

The polar movement (model L) of the filling head is optimized for the emptying 4 drums on pallets or IBC, it nevertheless allows the prompt emptying of cans on pallets. The motorized diving system (stroke 1200) with pneumatic actuator allows the ascent and descent of the suction tube in the container bottom with a blocking high and low position. Emptying is performed by manually opening the valve of suction tube triggered by the operator This configuration is ideal for barrel's emptying |

INTEGRATION OF YOUR EXISTING | |

|

|

MANAGEMENT DOSAGE PACKAGING | |

Different weighing infrastructure are proposed according to your needs

|

|

BASE CONFIGURATION | |

The base configuration includes:

Capacities: different format of barrel with bunghole or fully open and IBC containers Rates: following the flow of the pump, the viscosity of the product and local conditions, up to 30 barrels / h (50 barrels/h avec with conveyors) |

The base configuration includes:

Capacities: different format of barrel with bunghole or fully open and IBC containers Rates: following the flow of the pump, the viscosity of the product and local conditions, up to 30 barrels / h (40 barrels/h avec with conveyors) |

OPTIONAL EQUIPMENT | |

|

|