Cart 0 Product Products (empty)

No products

To be determined Shipping

0,00 € Total

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart. There is 1 item in your cart.

Total products

Total shipping To be determined

Total

Filling machines

DESCRIPTION

| DOMAINS OF USE

| ADVANTAGES

|

Série 1 axe | Série 2 axes | Série 3 axes | Série 4 axes | Série PCL |

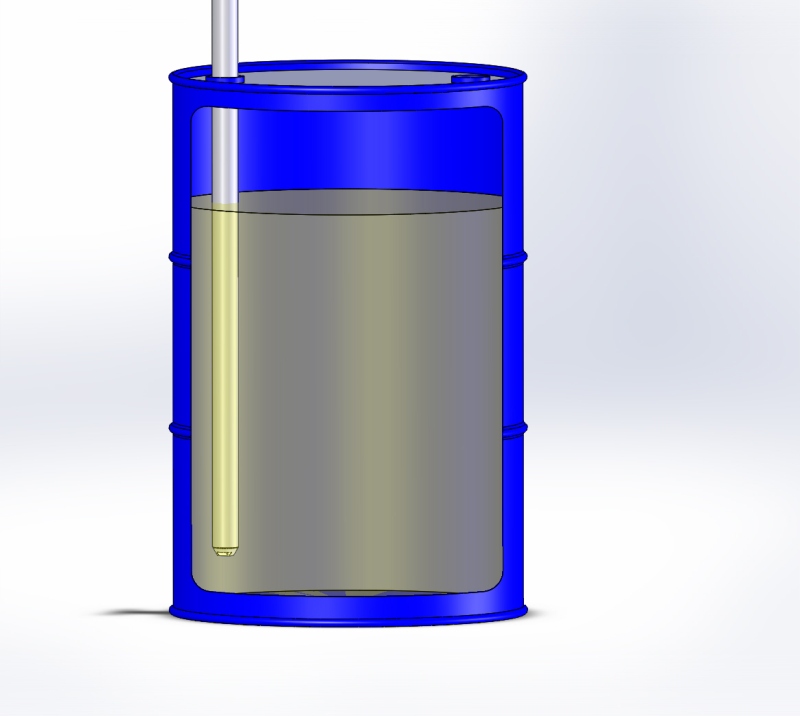

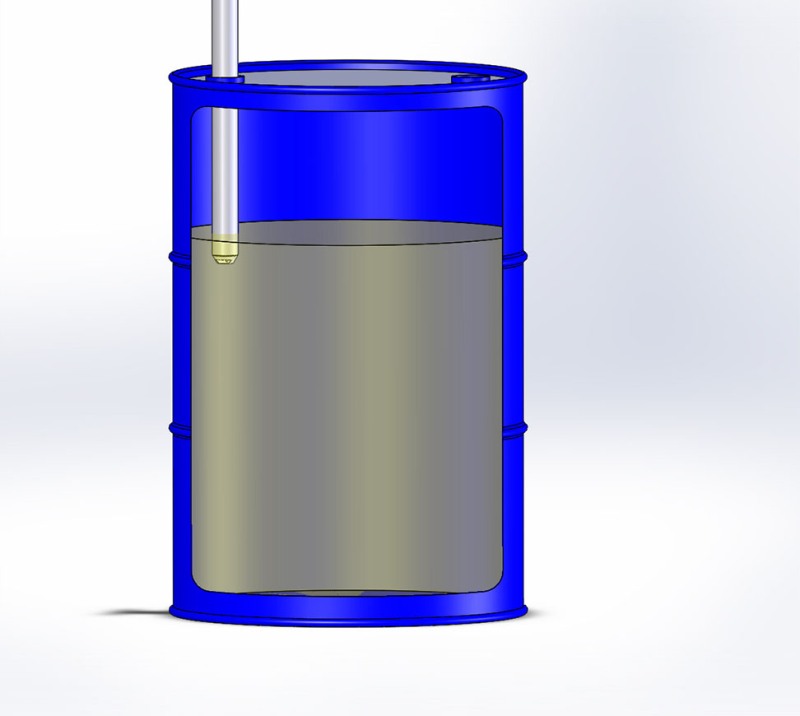

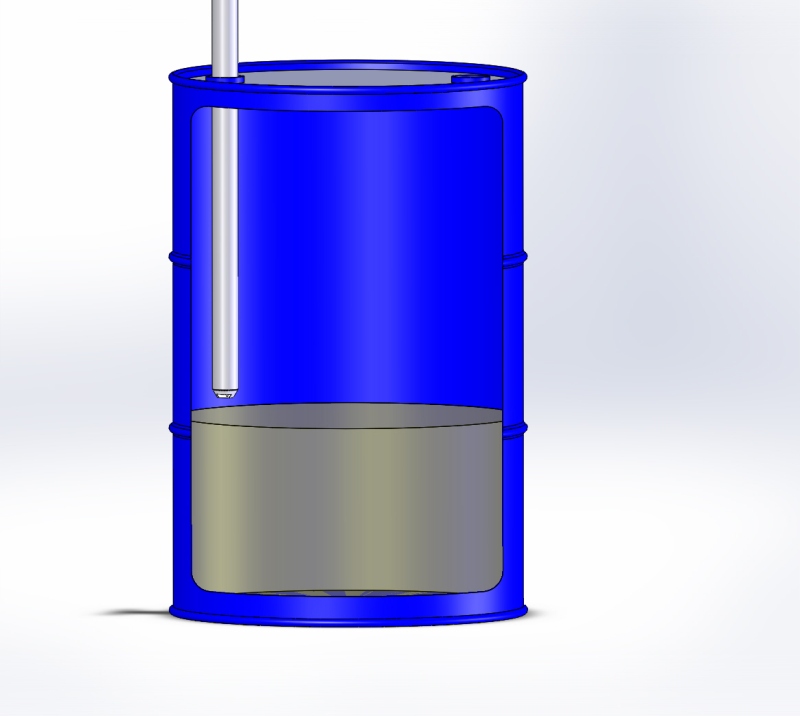

The filling can be effected by the use of a a dip pipe (XP model) for foaming products enabling:

- Dumping of cane

- The gradual rise above the level (filling over water)

- The gradual rise below the level (partial immersion of the cane

Under fixed level filling |  Filling in level over water |  Level on filling over water |

The filling may also be effected by the use of a non-dip pipe ( XNP model) for the non-foaming products allowing:

- The partial introduction of the cane under the bunghole of the container (filling fountain).

Fountain filling level |

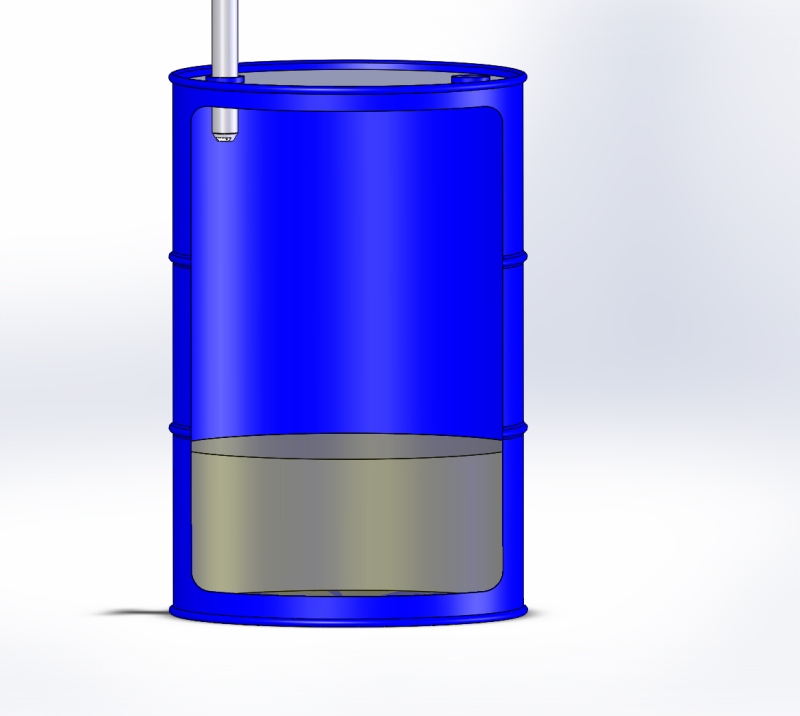

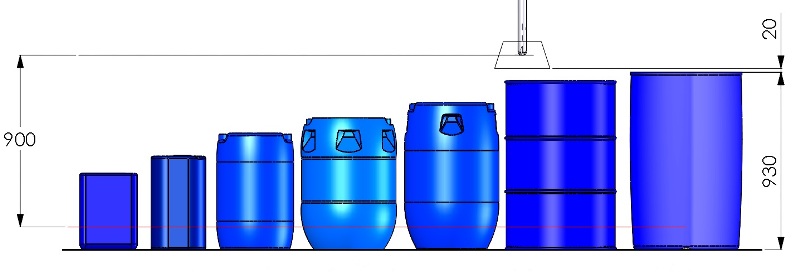

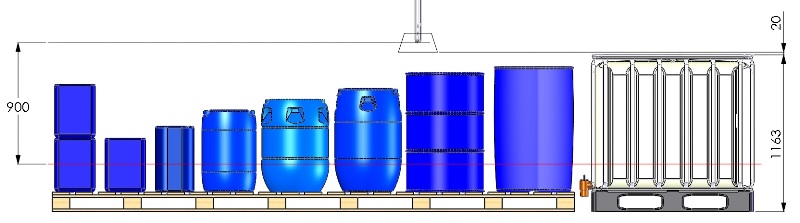

Our intelligent technology cane (only dip pipes XP model) allows managing multiple heights packaging (provided that the height of the packaging is between the rocker and in a high position cane)

|

Management of single-barrel packing heights |

|

Management of multi-barrels packaging pallet heights |

SpecificitiesSemi-automatic or manual filling station Fill mode of packaging

Cannes drumming

Vapor treatment and VOC (volatile organic compound)

| Construction

| EQUIPMENTStandard equipment or optional depending on model

| peripheral equipmentHandling and peripheral equipment can be integrated to fit your needs

|