Cart 0 Product Products (empty)

No products

To be determined Shipping

0,00 € Total

Product successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart. There is 1 item in your cart.

Total products

Total shipping To be determined

Total

EMPTYING AND FILLING LT SERIES

DESCRIPTIONFrom the legacy of our experience and our expertise in the drumming, the filling and emptying of the LT series offer very economical solutions including essential features of a drumming station.

| DOMAINS OF USEOur machines are designed for industrial exploitation.

| ADVANTAGES

|

1 AXIS LT SERIES | 3 AXIS LT SERIES |

XP MODEL MOTORIZED DIVING CANE | XNP MODEL PARTIAL DIVING CANE | |

|  |  |

|

|

|

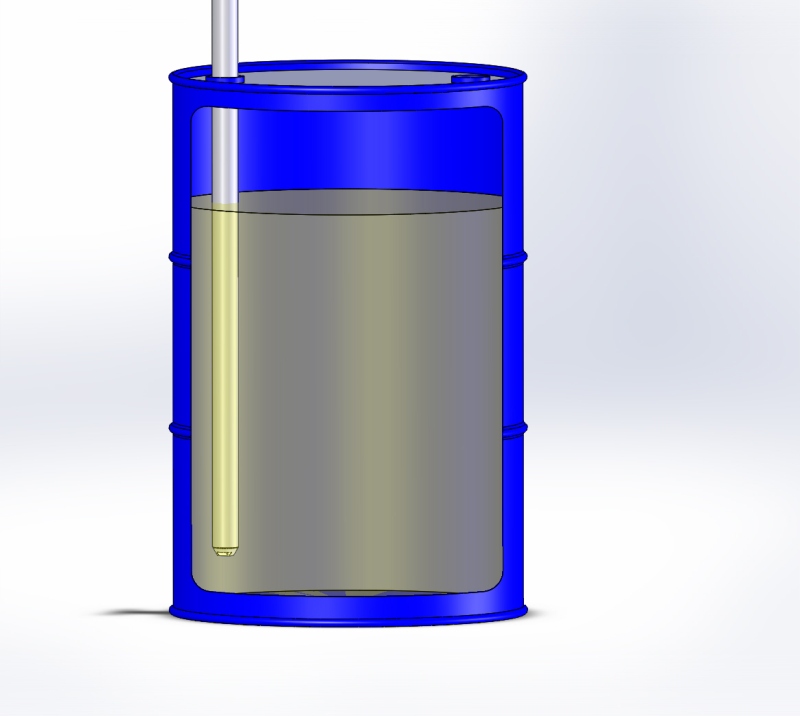

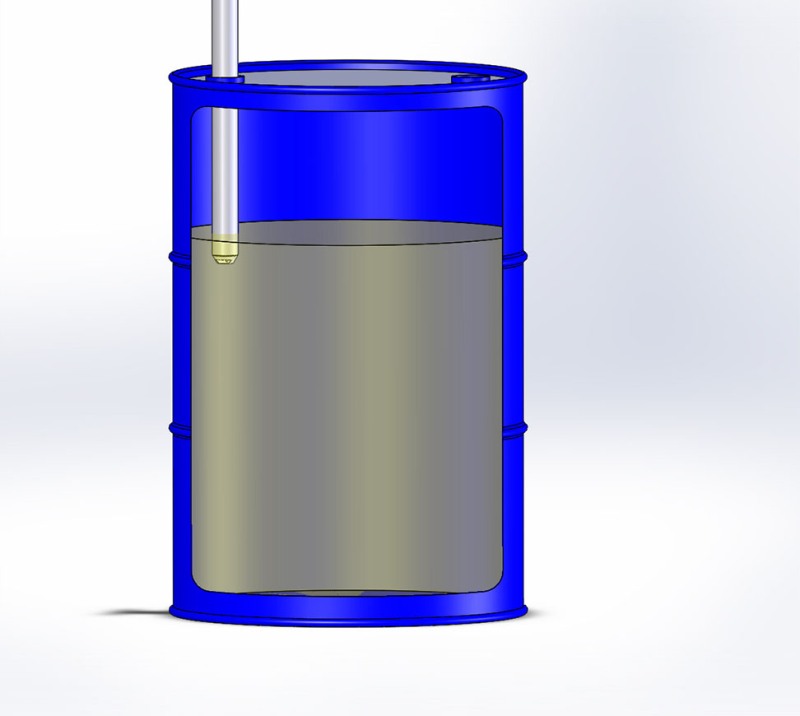

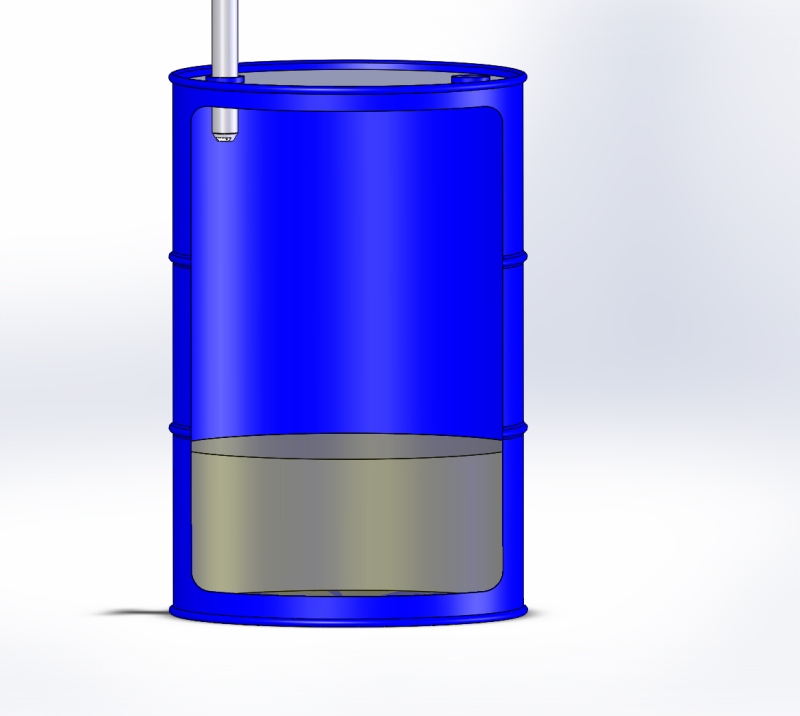

UNDER FIXED LEVEL FILLING | FILLING IN LEVEL OVER WATER | LEVEL ON FILLING OVER WATER |

SPECIFICITIESSemi-automatic or manual filling station Fill mode of packaging

Filling and emptying devices

| EQUIPMENTIN STANDARD OR IN OPTION

| PERIPHERALS EQUIPMENTSHandling and peripheral equipment can be integrated to fit your needs

Vapor treatment and VOC (volatile organic compound)

CONSTRUCTION

|