No products

View larger

View larger Accessories

More info

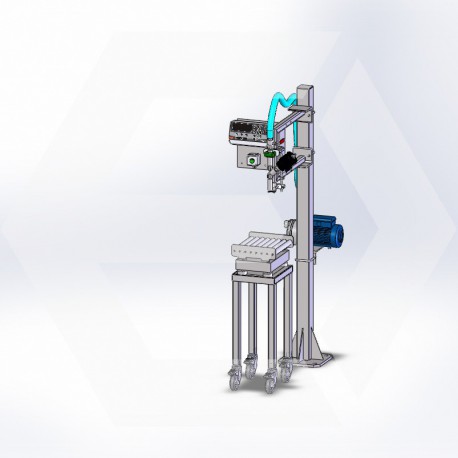

A recovery bracket made of welded steel designed to be fixed to the ground (may require civil engineering) or base plate.

A racking frame:

- Adjustable punctually in height.

- RPCL valve with height adjustment.

- Bung pointer with height and height adjustment.

Dosing valve set VSI 90° DN15 (3/6) ref 91-001-159 or DN20 (6/15) ref 91-001-20.

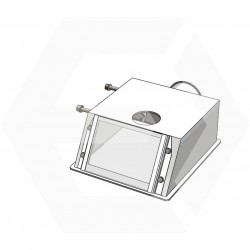

An electric polycarbonate box, IP66, IK10 placed on the stem ref 91-003-06.

Pneumatic components.

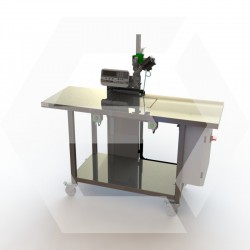

A stainless steel weighing table mounted on 4 swivel castors equipped with brakes to receive the rocker. Height relative to the ground estimated at about 700 mm.

A PRECIA weighing system built into the upper plate:

- Weighing scale 304L stainless steel.

- Stainless steel weighing pan.

- Station 3/6 kg Bi-extended range 0-3 kg / step 1 g and 3-6 kg step 2 g ref 91-004-19.

- Station 6/15 kg Bi-extended range 0-6 kg / step 2 g and 6-15 kg step 5 g ref 91-004-28.

- A weight indicator with dosage management by recipe.

- DSD alibi memory 300,000 μSD card recordings.

- A calibration check, metrological notebook and vignette supplied in NAWI.

The set is delivered fully assembled, ready for operation.

Technical file including manual handling, mounting and connection, use, maintenance, spare parts list, CE certificate.

DESCRIPTIONThe filling machine ERIFUT 1 XNP LT RPCL acid / base allows the packaging of non-foaming, pasty liquid products in small containers of different types. This configuration is ideal for filling bottles, cans.

| DOMAINS OF USEOur machines are designed for industrial exploitation.

| FUNCTIONAxis management:

Fill Management:

| ADVANTAGES

|

Data sheet

| Height | 1720 mm |

| Width | 400 mm |

| Depth | 700 mm |

| Weight | 100 kg |

| Use | Industrial use less than 1000 H / year |

| Rate | Up to 200 cans 1 L/h |

| Packaging | Cans, bottles |

| Product supply | Gravity, pump, pressure |

| Flow | Recommended 0.5 to 2 m^3/h / 3 bars max |

| Sound level | Less than 70 dB at 1m |

| General construction | As follows posts |

| Product circuit | Stainless steel, EPDM or VITON seals |

| Power supply | 230 V |

| Total power | 1 KW |

| Pneumatic supply | 6 bars clean and dry / 100L/h |

| Management height canes | Manually adjustable |

| Dive of cane | Fixed dosing cannula |

| Filling mode | On-level fixed |

| Managing multi-level packaging | Yes with manual settings |

| Diameter of the cane | Cannula diameter 15 or diameter 20 by default |

| Tube actuator | VSI DN15 or DN20 actuator, simple effect + security spring |

| Flow limiter | By manual valve DN15 or DN20 quarter turn |

| Cane outlet | Smooth straight jet outlet, optional anti-drop sieve |

| Viscosity | Up to 500 centipoises without a pump and 150 centipoises with pump ref.: 91-008-03 |

| Commercial transaction | Legal metrology in NAWI / OIML |

| Range / step | Bi-range 3/6 kg step 1/2 g or bi-range 6/15 kg step 2/5 g depending on version |

| Tare | Automatic controlled filling |

| Alibi memory | 300 000 records |

| Dosing | Recipe weight and jetty error correction |

| Tolerances mini / maxi | Tolerance thresholds min / max |

| Management dosage packaging | Automatic filling according to a target weight |

| Documentation | Technical file including manual handling, mounting and connection, use, maintenance, spare parts list, EC certificate |

| Filling functions | Auto fill mode |

| Packaging detection | Yes |

| Customer pump control | 1 digital output |

Ask a question

NO registration required!

If the question you have has not yet been answered here, use the form below to ask something about this addon.