No products

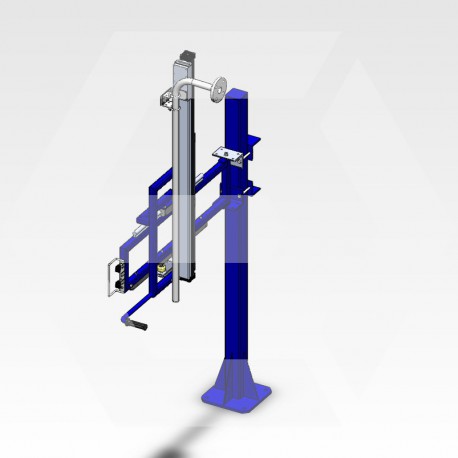

ERIFUT 3 XP LT DF

New product

ERIFUT 3 XP LT DF allows deconditioning of liquids produced by the complete introduction in the container, a suction plunger tube connected to a suction pump. (Not supplied ERIMAC)

Machine sold with dip tube diameter 40 mm, stroke 1200 mm

To order - deadline 5-6 weeks

Accessories

More info

DESCRIPTIONERIFUT 3 XP LT DF allows deconditioning of liquids produced by the complete introduction in the container, a suction plunger tube connected to a suction pump. (Not supplied ERIMAC). Conventional solutions manual emptying by dip tube or vacuum pump was expose the operator, fumes and splashing fluid in direct contact during the handling and emptying operations. The filling machine ERIFUT 3 XP LT DF replaces or combines advantageously existing conventional solutions.Improves conditions of handling and operator exposure in an improvement process complies with REACH requirements.

This configuration is ideal for the filling of 4 barrels on pallet or a container.

| DOMAINS OF USEOur machines are designed for industrial exploitation.

| FEATURESMotion control

Filling Management

| ADVANTAGES

|

Data sheet

| Height | 3 100 mm |

| Width | 2 229 mm |

| Depth | 2 500 mm max |

| Weight | 155 kg |

| Use | Industrial use less than 1000 H / year |

| Packaging | Jerrican, drum and container |

| Flow | Advocated 8 m³/h |

| Sound level | Less than 70 dB at 1m |

| General construction | Painted steel rust protection |

| Product circuit | Stainless steel 316L |

| Power supply | No need of electricity |

| Pneumatic supply | 6 bars clean and dry / 100L/h |

| Management height canes | motorized diving system |

| Dive of cane | Filling lance diving emptying drum (course 1200) |

| Managing multi-level packaging | Yes with manual settings |

| Diameter of the cane | Diameter 40 mm default |

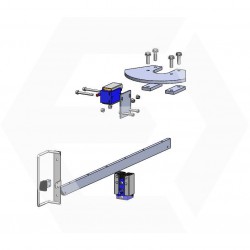

| Rotation and translation braking | Optional |

| Documentation | Technical file including manual handling, mounting and connection, use, maintenance, spare parts list, EC certificate |

Ask a question

NO registration required!

1 Question(s) answered

If the question you have has not yet been answered here, use the form below to ask something about this addon.

- Asked by Alexandre Patoux

on 2022-11-02 Bonjour Je suis chef de service "Energie et Utilités" à l'usine SOLVAY de Dombasle. Je suis à la recherche d'une solution safe pour la vidange de produit chimique type WAC et NaClO qui arrivent en IBC (1m3). Les opérateurs réalisent une série d'opérations avec contact potentiel avec les produits. J'aimerais diminuer le risque associé.La solution de desenfutage ERIFUT 3 XP LT DF attire mon attention quand bien même elle semble sophistiqué par rapport à mon besoin. Je me demande si des solutions de desenfutage plus basqiues pourraient être proposées (à l'instar de la ERIFUT 1 XNP LT MANU, mais avec une course d'env. 1m pour la canne plongeante). Je me demande également si vos produits sont comptables avec un fonctionnement 365j par an en reliant la canne à une petite pompe doseuse.Merci d'avance pour votre retour, je me demande si un produit de votre gamme pourrait correspondre à notre besoin.Cordialement Answer: